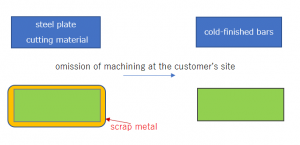

Contribution to the improvement of our customers' production effiency

Customers always require “more precise and lower costs” materials.

Compared to similar materials produced by cutting steel plates or cutting hot-rolled steel bars, Kansai Metal’s cold-finished steel bars provide a higher and more stable level of precision, not only solving problems related to the material itself, but also helping our customers improve their overall production efficiency.

Introducing our diverse product lineup

POINT 01

Dimensional Accuracy

1.Our 90 years of experience and technology ensure the accuracy required by our customers through appropriate processing methods.

2.The improvement effect of yield rate by near-net-shape processes is especially noticeable in stainless steel, where the material cost is high, the life of cutting tools is short, and cutting speed is slow. Therefore, the use of cold-finished steel bars with high dimensional accuracy can result in increased production output.

POINT 02

Deviation in diameter

<In Round bars>

The difference between the maximum and minimum diameters in the same cross section is also strictly controlled, enabling material closer to a perfect circle at a lower cost.

POINT 03

Straightness

The excellent straightness and small variation within a product lot allow long materials to be used in automated production lines (NC automatic lathes with bar feeders) with confidence.

By reducing short time breakdown in the automated production line, we expect to increase production efficiency at our customers and improve the accuracy of production control.

POINT 04

Surface finish

The excellent surface finish unique to Kansai Metal’s “cold-finished steel bars” can be used directly without any post-processing in situations where appearance quality is required.

POINT 05

Flatness

<In Square/Flat/Hexagonal Bars>

The surface of cold-finished bars can be used as it is in many applications. Total cost reduction can be expected by eliminating the surface polishing process at the customer’s site. See here for the detail of dimensional tolerance.

To guarantee dimensional accuracy, surface finishing via turning, milling, or surface grinding is required

Increase in capital investment

A large amount of swarf is generated

A large manufacturing facility is required